Screen printing is a versatile and popular method of applying designs to various surfaces, predominantly textiles. It is an essential technique for creators wishing to bring their designs to life. However, for many artists, entrepreneurs, and hobbyists, cost can be a critical factor. Embracing budget-consciousness is not just about saving money—it’s about optimizing resources and maximizing creative output.

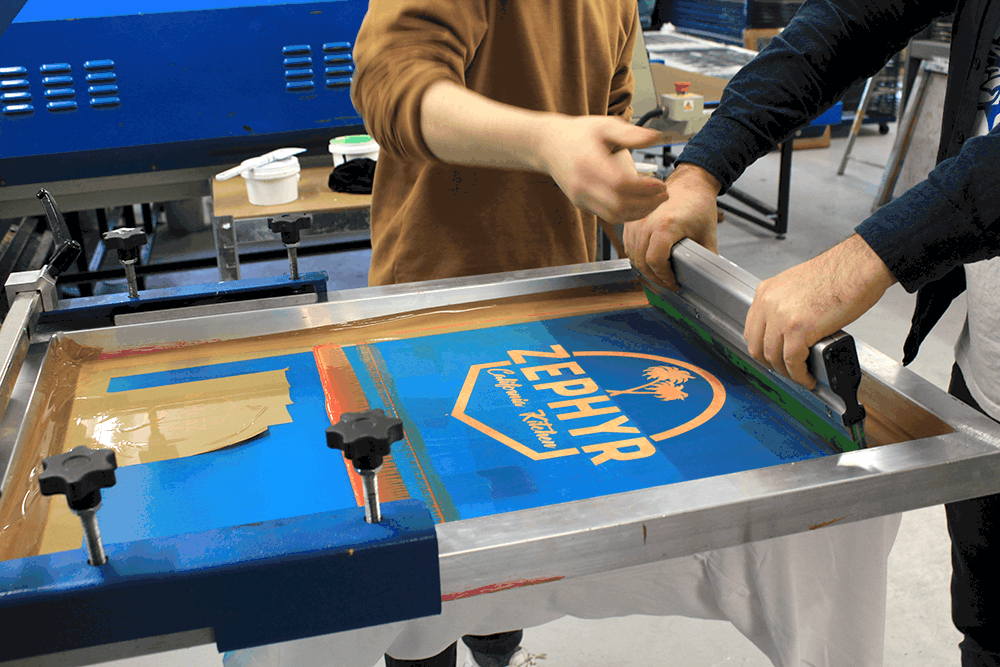

Screen printing, at its core, is a technique that uses a woven mesh to support an ink-blocking stencil. The attached stencil forms open areas of mesh, transferring ink as a sharp-edged image onto a substrate. A fill blade or squeegee moves across the screen stencil, pushing or pumping ink through the open areas.

Key components for screen printing include screens, squeegees, inks, and a substrate to print on. Understanding each element is pivotal, as it allows creators to make informed decisions, optimizing cost without compromising quality. Beginners should focus on learning the interplay of these components, mastering the subtleties of applying pressure, and understanding ink viscosity and screen tension.

Table of Contents

Setting a Budget

Establishing a budget is pivotal for maintaining cost-effectiveness in screen printing projects. It involves evaluating the scale and scope of the project, including the quantity and quality of materials needed and the intended detail of the designs.

To determine a realistic budget, begin by listing all necessary materials and equipment such as silk screens for screen printing. Researching prices and suppliers is essential to identify the most cost-effective options. Additionally, factor in potential mishaps and overruns to avoid any unforeseen expenditures. Allocating funds judiciously to each component ensures a balance between quality and cost, preventing compromises that could affect the final product.

DIY vs. Professional Printing

DIY screen printing is often more budget-friendly, offering a hands-on approach and providing learning opportunities. It allows for more control over the process and can be more cost-effective for small runs. However, the initial investment in equipment and learning curve can be daunting.

Professional printing services, on the other hand, leverage expertise and specialized equipment to deliver high-quality results. They are particularly beneficial for large, complex projects where precision and consistency are crucial. While this option may seem more expensive, it can be more cost-effective in certain scenarios, especially when time and quality are paramount.

Choosing the Right Equipment

Selecting the right, budget-friendly equipment is crucial. Beginners should consider starting with entry-level kits that include essential tools. Investing in a reliable yet affordable screen printing machine, with the potential for upgrades, is sensible.

Different types of equipment offer varying levels of efficiency, precision, and versatility. For instance, manual screen printing presses are more affordable and suitable for small-scale projects, while automatic presses are ideal for high-volume printing but come with a higher price tag. Evaluating your project’s needs and aligning them with equipment capabilities ensures optimal investment and future-proofing.

Selecting Inexpensive Inks and Supplies

Inks and supplies are recurring expenses, making their selection crucial. Opt for inks that balance quality with affordability and consider the longevity and durability of the ink on your chosen substrate. Wholesale suppliers often offer better prices on bulk purchases, so researching and comparing prices can lead to significant savings.

Additionally, seeking out discounts, utilizing coupons, and buying in bulk during sales can reduce costs. Exploring different suppliers, both online and offline, enables access to a wider range of options, allowing for informed, cost-effective choices.

Optimizing Design for Efficiency

Design choices profoundly impact printing costs. Simple designs with fewer colors are generally more affordable to print. It’s essential to balance aesthetic aspirations with budget constraints, optimizing designs for efficiency without compromising on artistic vision.

Vector graphics, with their scalability and precision, are ideal for screen printing. By minimizing the color palette and simplifying details, creators can reduce the number of screens and the amount of ink required, subsequently lowering costs while maintaining design integrity.

Minimizing Waste

Efficient resource utilization and waste minimization are key to budget-friendly screen printing. Using the exact amount of ink and properly maintaining screens reduces material wastage and extends the life of your tools.

Developing eco-friendly practices not only contributes to environmental conservation but also enhances cost-effectiveness. Reusing and recycling materials, properly disposing of waste, and optimizing the use of inks and other supplies are pivotal in minimizing the environmental footprint and maintaining cost efficiency.

Printing on a Variety of Surfaces

Screen printing can be adapted to a multitude of surfaces, including textiles, ceramics, wood, and paper. Each surface requires a unique approach, affecting cost. Understanding the nuances of printing on different materials enables creators to optimize processes and maintain budget-friendly practices.

Adapting the printing process according to the substrate’s characteristics ensures better results and longevity of the print. This approach, coupled with a careful selection of inks and materials, allows for versatile, cost-effective printing across diverse projects.

Bulk Printing and Group Orders

Bulk printing and group orders are effective strategies for cost reduction. They enable economies of scale, lowering the per-unit cost of each print. Managing group orders efficiently involves clear communication about design specifics, order quantities, and timelines, ensuring satisfaction and minimizing revisions or reprints.

Developing a systematic approach for handling multiple orders simultaneously maximizes efficiency and ensures consistent quality. It helps in reducing errors and managing resources effectively, ultimately leading to better cost management.

Maintenance and Longevity

Proper maintenance of screen printing tools and equipment is crucial. It prolongs the life of your tools, reducing the need for replacements or repairs. Regular cleaning of screens, proper storage of inks, and routine checks on equipment ensure optimal functioning and longevity.

Understanding the maintenance requirements of each component and adhering to recommended practices preserves the quality of prints and ensures a smoother, more efficient printing process, reducing long-term costs and ensuring sustained productivity.

Conclusion

Budget-friendly screen printing is achievable through informed decisions, resource optimization, and strategic planning. Understanding the basics, setting realistic budgets, choosing the right equipment and supplies, optimizing designs, and minimizing waste are pivotal steps in creating cost-conscious, high-quality screen prints.

Every creator, whether a novice or a seasoned professional, can benefit from implementing these budget-friendly tips in their screen printing endeavors. The amalgamation of cost-consciousness and creative ingenuity not only fosters artistic expression but also promotes sustainability and resourcefulness in the screen printing process.

Remember, being budget-conscious doesn’t mean compromising on quality or creativity—it means optimizing resources to bring visions to life in the most efficient way possible. The journey of screen printing is filled with learning and exploration, and with a mindful approach, it can be both economically and artistically rewarding.